About

Who we are

Ramco is quality manufacturing company. We are committed to providing quality – machining parts to your specification and on time deliveries by using stringent quality control procedures. For over 30 years Ramco has been in precision machine work, for manufacturing, prototype, production, aircraft, and more. Whether you need a prototype or high – volume production, Ramco can apply the latest technologies and skills sets to achieve low development and production costs.

- Ramco has seven CNC machines

- Can perform 2 axes lathe operations and 3,4 mill operations

- Coupled with manual mills and lathes, we are well equipped to meet your needs.

Ramco has the capabilities to perform large volume production runs without impacting other projects. Also, Ramco is structured in manner which providers a “backup” machine should we incur any down time. This structure assures our customers timely deliveries.

Have Questions?

With 30+ years of solid industry experience and multiple happy customers we can help you with your machinery needs. Contact us today to learn more.

Services

What we do offer

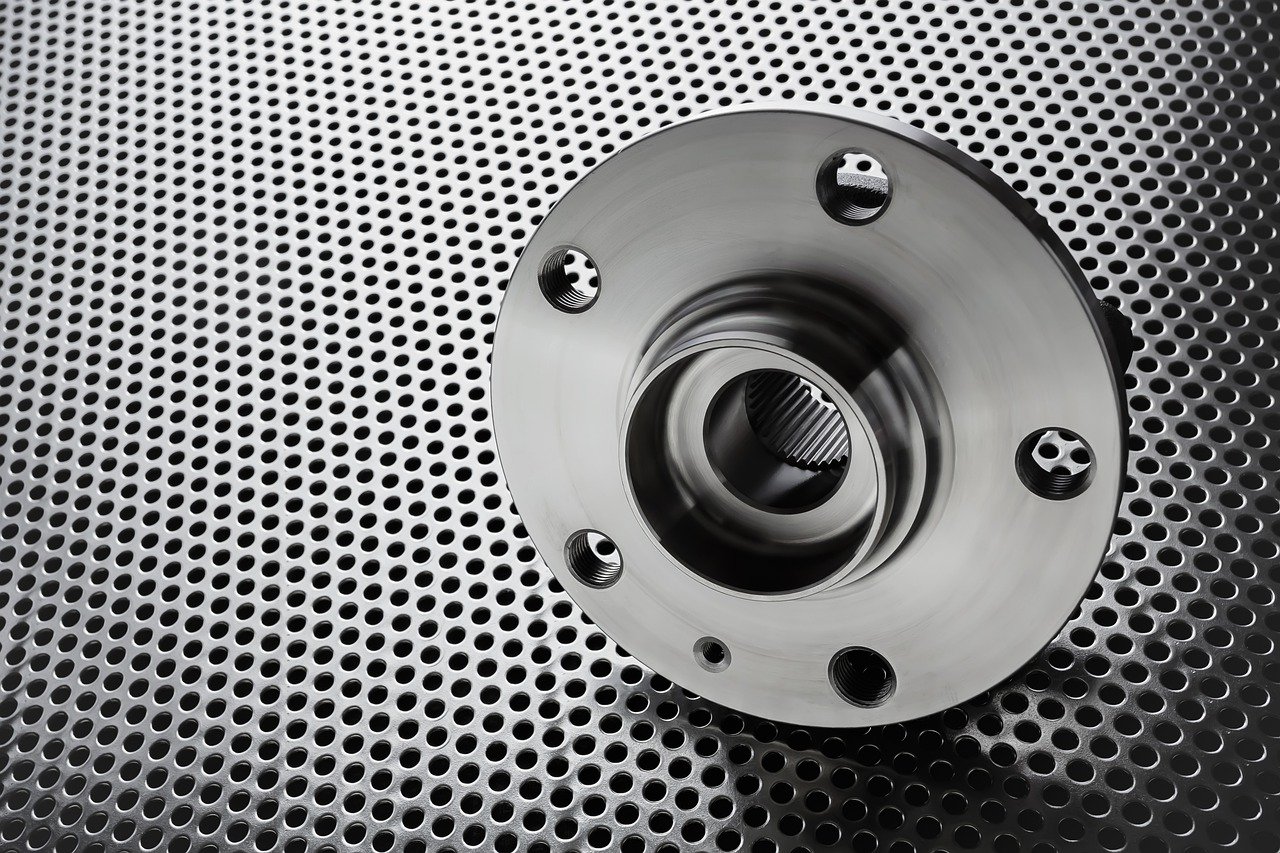

Precision Machining

CNC Machines are the cornerstones of our business. This commitment to technology assures accuracy while reducing cost.

Large Volume Production

Ramco has the capabilities to perform large volume production runs without impacting other projects.

Backup Setup

Ramco is structured in manner which provides a “backup” machine should we incur any down time.

Solid Experience

Ramco resources provide the people, tools and know – how for machining and delivering high quality products on time.

Equipment

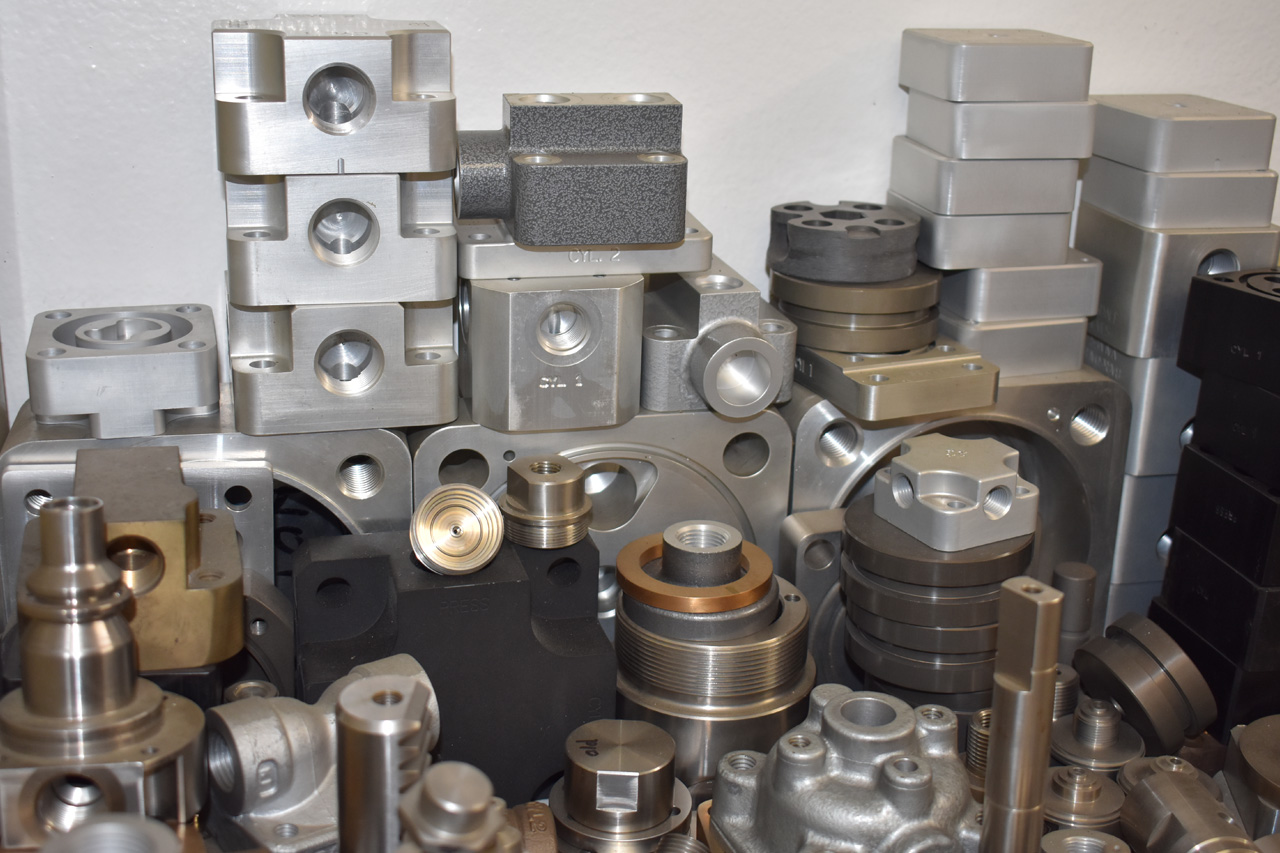

RAMCO FACILITIES BRIEF

Ramco maintains an excellent modern complete machine shop supporting customer production as well as internal requirements for fixturing and equipment modification. Our machine shop facilities are complete. Ramco resources provide the people, tools and know – how for machining and delivering high quality products on time.

MACHINE SHOP EQUIPMENT INCLUDES:- Four CNC Mori Seiki Lathe AL – 2, 8” Chuck, 8 tools capacity

- Fanuc 10T Control spindles tub 13/4 travels 19.7” x 5.9 stroke

- One CNC Hitachi Seiki Lathe HVP 20 10” Chuck, 12 tools capacity Yasnac Control travels 15.7 x 6.1 with bar feed

- Two CNC Hitachi Seiki Hitec-Turn 20SII Lathe 10” Chuck, 12 tools capacity Multi Control travels 15.7 x 6.1

- Five CNC Mori Seiki Vertical Milling Machine MV Junior Four Axis Fanuc Control 10M travels X22” Y16”Z18”

- One CNC Mori Seiki Vertical Milling Machine VS50 travels X40” Y20”Z24”

- One CNC Mazak Vertical Milling Machine M-32B Four Axis Travels X22” Y16”Z18”

- One SMEC SL 20E 2-Axis Horizontal Lathes 8" (A2-6) Box Way

- Automatic Saw Amada HA 250

- Three gage block sets

- Three granite surface plates

- Two Mitutoyo height gages

- One J&L optical comparator

- Gages, Dial Bore, .18” to 16”

- Micrometers; Ball, Disc, and Groove

- O/D Pitch Micrometers 1” to 6”

- O/D Micrometers 0” to 16”

- Mitutoyo height Master gage 12”

- Completely equipped inspection

Contact

Contact Us

Location:

11577 Slater Ave. Ste H, Fountain Valley, CA 92708